Air Atomizing Spray Nozzles

Air Atomizing spray nozzles

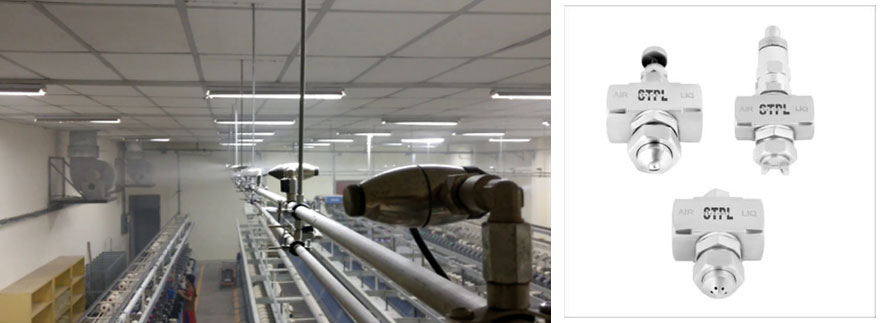

Spraynoz technologies private limited (STPL) is one of the trendsetters in the market regarding the manufacture of Air atomizing spray nozzles that are useful to mix air and liquid to result in a mist-like formation. Using the tool can help you get fine drops as when you get in spraying liquid. These can be adjusted as per the liquid capacity you wish to have. The compressed air can be used for increasing the efficiency of atomization through the nozzles. If you wish to have small sized droplets from the nozzles for a certain flow rate, then use the compressed air and modify the pressure.

In air atomizing spray nozzles will have two inlets, one is the liquid inlet and the other is the air inlet. The air atomizing spray nozzles give two different spray pattern, one is round/full cone spray pattern and one is flat fan spray pattern. Spraynoz technologies private limited (STPL) offer these kinds of spray nozzles in different sizes and features. In addition, the nozzle is simple in application and can be easily attached to the changeable parts. If you are looking to have a good moisture effect with the best moisture control, then air atomizing spray nozzles can be the right choice.

Compressed air is used to increase the atomization efficiency of these nozzles. A smaller droplet size for a given liquid flow rate can be obtained with the use of compressed air than can be obtained with nozzles that only use the pressure of the fluid.

Applications of air atomizing spray nozzles

These tools can be used in numerous ways, some of the common ones include:

❖ Cooling

❖ Granulation

❖ Tablet coating and pallet coating

❖ Agglomeration

❖ Atomizing of viscous liquids

❖ Humidification of air

❖ Mold lubrication

❖ Spraying injection

❖ Wool spraying

❖ Air disinfectant

Types of air atomizing spray nozzles

There are basically two types of spray nozzles that are manufactured by Spraynoz technologies Private Limited (STPL)

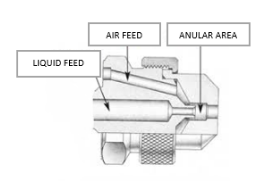

1.Internal mix: As the name suggests, the air and liquid will get mixed inside and the discharge will happen from orifice.

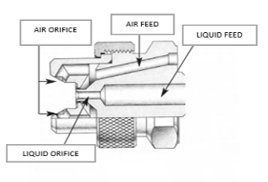

2. External mix: The liquid and air will get mixed outside and there are different orifice and discharge points.

Principle setup of the air atomizing spray nozzles

There are three setting up ways as follows.

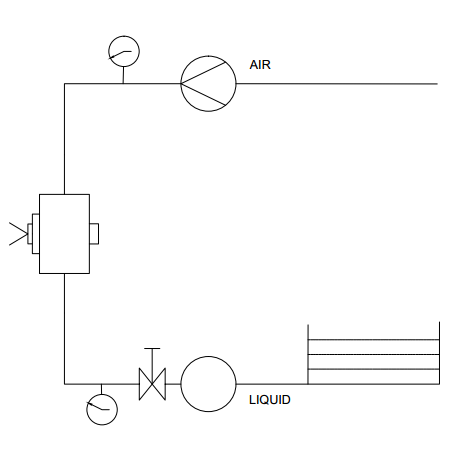

1. Pressure principle setup: The supply of liquid is from the pressure pump, which works for the compressed air.

2. Gravity principle setup: Here, the supply is from the gravitational head, which is also for the compressed air.

3. Siphon principle setup: The liquid is lifted without the need of the pump, and it also works for the compressed air.

To know how the model works, you can check out the webpage for the model/diagram in our website link https://www.spraynoztechnologies.com/

If you are looking for the best and premium quality of air atomizing spray nozzles, then you can get the quote from us. Contact Spraynoz technologies private limited (STPL) anytime for more information on the same either through email or call us directly.

Applications :

- ❖ Atomizing of viscous liquids

- ❖ Granulation

- ❖ Humidification of air

- ❖ Agglomeration

- ❖ Tablet coating

- ❖ Pallet coating

- ❖ Cooling

- ❖ Others

Internal Mix Air- Atomizing spray nozzles

In these types of spray nozzle air and liquid mix internally inside the cap and discharges from same orifice.

External Mix Air- Atomizing spray nozzles

In these types of spray nozzle air and liquid mix externally outside the cap from different orifice and discharges.

Air atomizing spray nozzles have following principle set-up.

1. Pressure Principle Set - up

2. Gravity Principle Set - up

3. Siphon Principle Set – up

1) Pressure Principle Set - up

Liquid supplies from pressure pump and for compressed air, compressor requires.

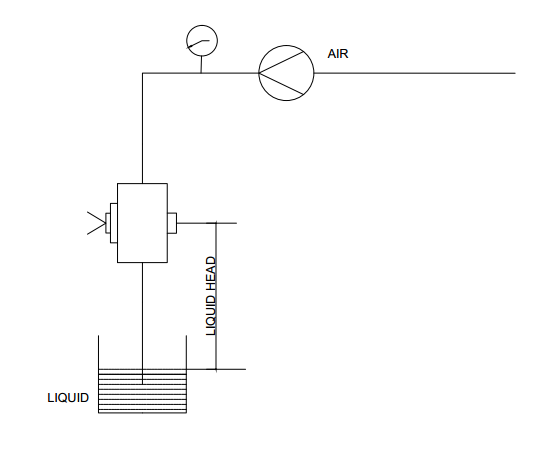

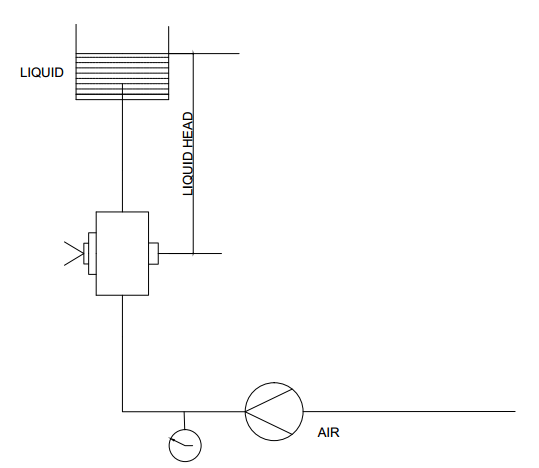

2) Gravity Principle Set – up

Liquid supplies from gravitational head (no need of pump) and for compressed air, compressor requires.

3) Siphon Principle Set - up

Liquid lifts at certain height (no need of pump) by the compressed air and for compressed air, compressor requires.